Sennebogen Electric Drive

Sennebogen Electric Drive: Revolutionising Material Handling

Sennebogen Electric Drive Material Handlers are designed for efficiency and sustainability, providing powerful solutions for various industrial applications. With the Sennebogen electric drive, these electric material handlers offer an environmentally friendly alternative to traditional diesel engines.

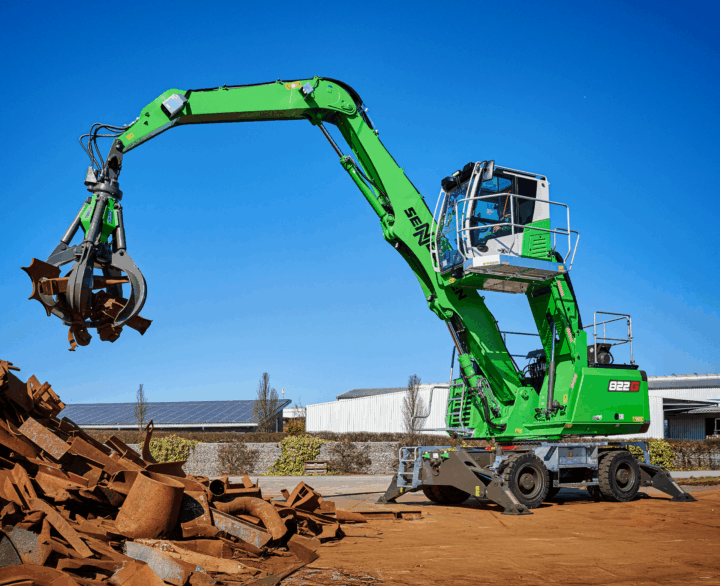

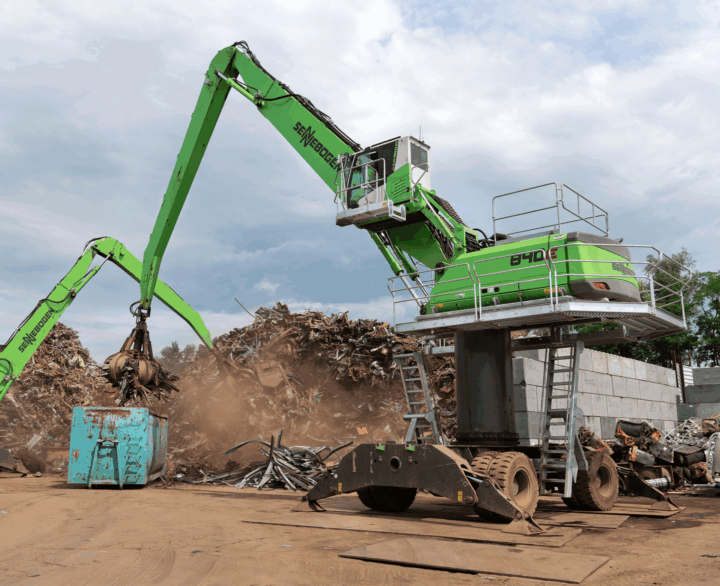

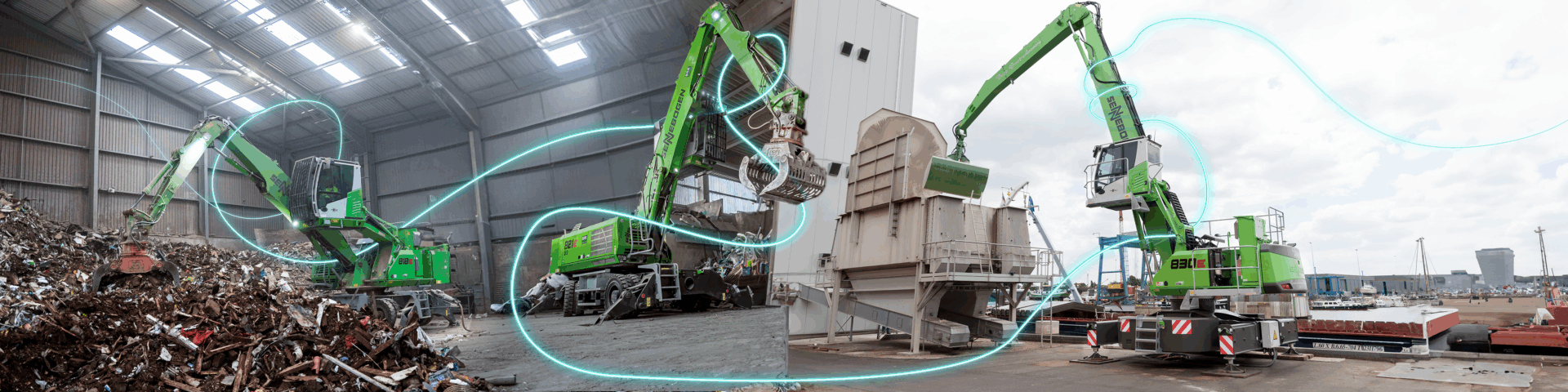

Looking for a sustainable, cost-effective solution for material handling? Sennebogen Electric Drive material handlers deliver exceptional efficiency, reduced operating costs, and lower emissions. Available in two configurations, mains-connected (cable-powered) and battery-operated, these machines feature an electric motor and electric travel drive, designed to meet diverse operational needs across the recycling, scrap, and port industries. The electric drive motors not only enhance performance but also contribute to a reduction in noise levels, making them ideal for stationary applications.

Get The Right Machine For Your Needs

Mains Connected Drive

Continuous power via mains connection – ideal for stationary operations with up to 50% lower operating costs.

Battery Electric Drive

Lithium-ion battery for full mobility – 6 hours runtime plus simultaneous charging when connected to mains.

Onboard Gen set for Full Independence

An integrated diesel generator powers the machine when mains electricity is unavailable, ensuring smooth operations in any location.

Which option is best for you

Mains Connected Drive

Mains Connected Drive

Perfect for stationary applications or sites with limited mobility, Sennebogen tethered electric drive handlers connect directly to the mains for a continuous power supply, eliminating downtime for refuelling. These electric material handlers are designed to enhance material handling efficiency while offering operating costs that are significantly lower than traditional diesel machines. Customers can experience a reduction in noise levels and improved green efficiency drive while enjoying the robust performance of Sennebogen machines.

Key Benefits:

- Up to 50% lower operating costs compared to diesel engines

- Minimal maintenance with fewer service intervals

- Ideal for long-term, high-demand operations

Battery-Operated Electric Drive

Battery-Operated Electric Drive

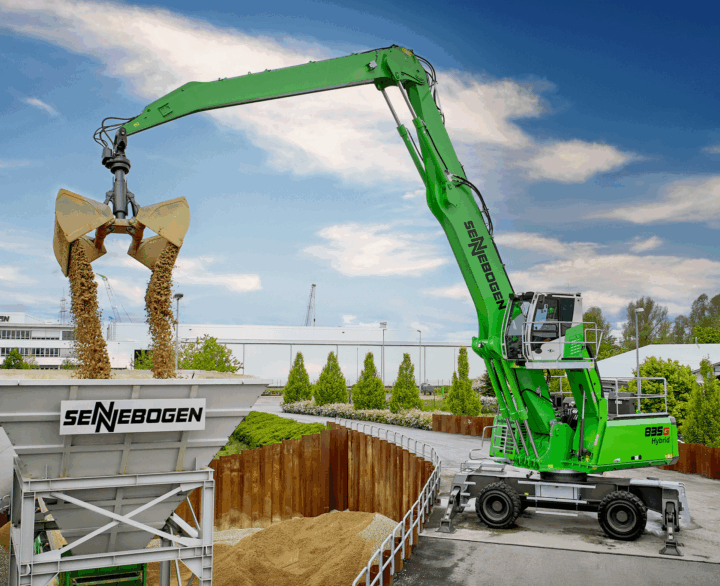

Designed for maximum mobility and zero emissions, Sennebogen battery-powered material handlers offer a clean, quiet, and efficient solution for modern handling operations. Powered by advanced battery technology, these machines eliminate the need for fuel and offer extended operating times, complemented by fast charging options. Perfect for indoor environments or areas with strict emission regulations, battery handlers combine sustainability with uncompromised performance.

Key Benefits:

- Zero emissions for environmentally sensitive applications

- Low noise levels for improved operator comfort

- Flexible operation with fast-charging capabilities

Onboard Gent Set Drive

Onboard Gent Set Drive

Gen set for working, if electric mains are not available at all working areas, a full-size generator can be supplied, allowing the flexibility of working on a mains connection and “off grid” via the full-size dowse generator

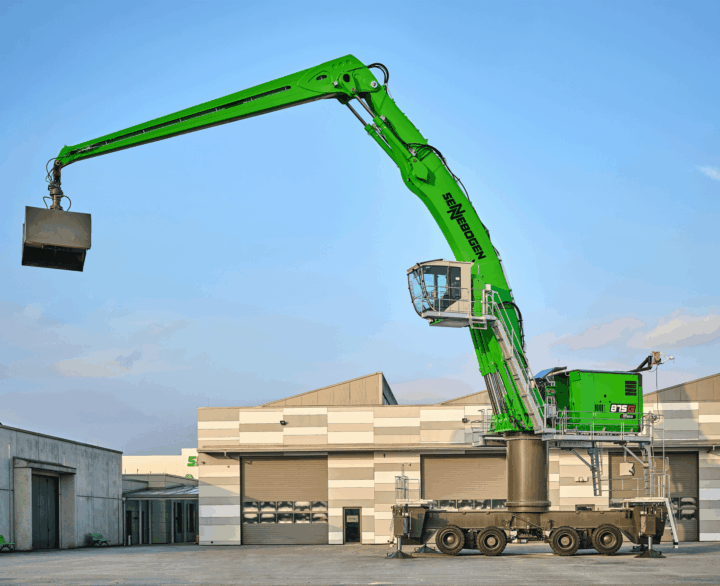

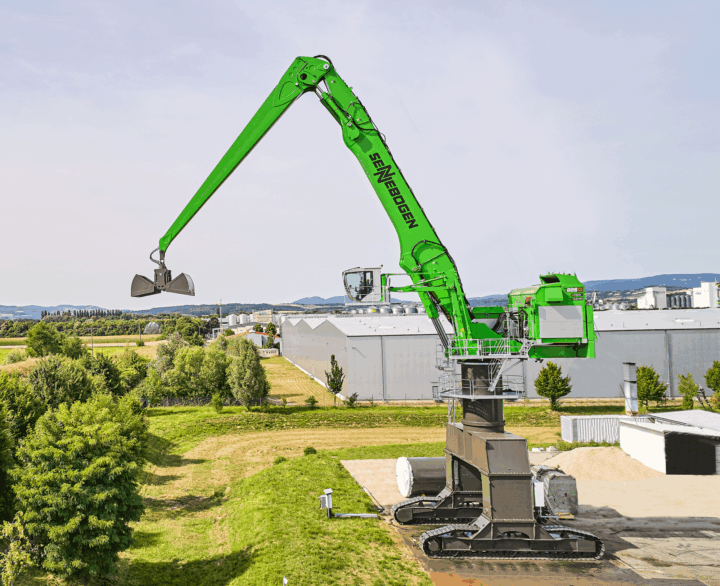

Power for Heavy-Duty Port Applications

For heavy-duty port handling and bulk material operations, Sennebogen offers an onboard genset option on its larger electric machines. The integrated diesel generator powers the electric drive when a mains supply isn’t accessible, ensuring uninterrupted operation in demanding environments. This setup combines the efficiency of electric technology with the mobility and autonomy required for large-scale port logistics.

Key Benefits:

- Independent operation without external power

- Maintains full mobility for large, dynamic port sites

- Ideal for bulk-handling, recycling, and harbour applications

- Environmentally friendly solution thanks to the electric drive

- Reduced operating and service costs with longer service intervals

Why Choose Sennebogen Electric Material Handlers?

Sennebogen electric material handlers are changing the game for modern, sustainable operations. They’re not just better for the planet, with up to 50% lower energy costs and significantly reduced CO₂ emissions, they’re also easier to live with day to day. No oil changes, no fuel filters, and far less maintenance overall means less downtime and fewer headaches.

Operators appreciate the quiet, smooth electric drives that reduce noise and vibration, creating a more comfortable working environment, especially indoors or in enclosed spaces. And because they produce fewer emissions, they’re ideal for improving air quality in dusty or confined areas where diesel engines struggle.

With longer service intervals and a clean, reliable power supply, these electrically powered material handlers retain their value and continue to perform over time. Backed by over 30 years of experience, Sennebogen has developed electric solutions to suit every need, whether it’s a material handler with electric travel drive, lithium-ion mobility, or the flexibility of an onboard genset. It’s smart, sustainable, and built to last, embodying the green efficiency drive in material handling.

Ashvin Metals New Sennebogen 835G Hybrid

Stay Updated with the Latest on Sennebogen Electric Drive

Explore the newest updates, insights, and innovations around Sennebogen’s electric drive technology. From product highlights and energy-saving benefits to behind-the-scenes developments and industry trends, this is your go-to source for everything related to sustainable material handling with electric power.

October 22, 2024

October 22, 2024