Finlay I-120RS Electric

Specifications

Finlay I-120RS electric drive impact crusher with onboard recirculating screen

Efficient Finlay I-120RS impact crusher with integrated after-screen

The electric drive Finlay I-120RS combines heavy-duty imoact crushing performance with a fully electric power option, delivering lower running costs, reduced emissions, and superior efficiency for quarrying, mining, construction, and recycling operations. Designed with an integrated recirculating post-screen system, the I-120RS impact crusher enables operators to produce a consistent, high-quality product with minimal setup and reduced need for additional screening equipment, enhancing material flow and production capabilities.

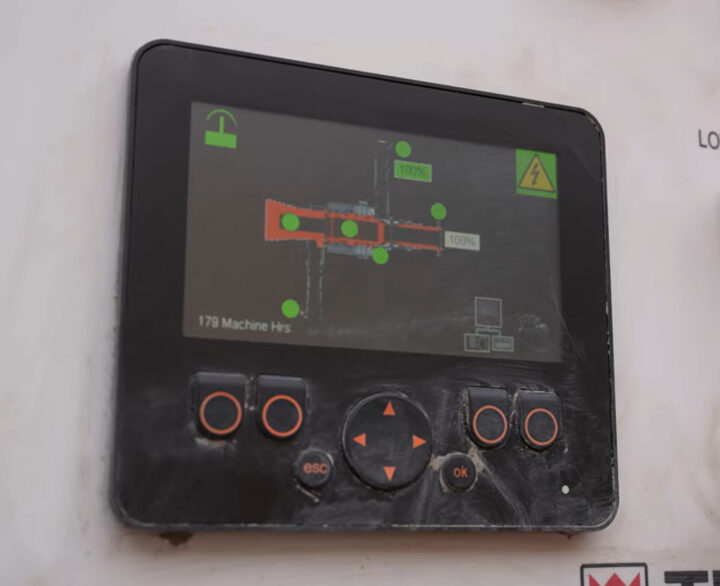

Engineered for modern job sites, the I-120RS Electric offers flexible power supply (plug-in or onboard genset), ensuring reliable operation even in remote locations. With advanced load-sensing hydraulics, intelligent control systems, and a focus on operator safety, this impact crusher sets a new standard in long-term sustainability and compliance, making it a wise choice for those investing in electric powered equipment. The direct drive system powers the feeder, contributing to productivity and efficiency in operation.

Key Features of the electric drive I-120RS

Integrated Recirculating Post-Screen System

Integrated Recirculating Post-Screen System

One of the standout features is its onboard two deck screen with recirculating conveyor. This system ensures material is sized and classified directly within the crusher, reducing the need for secondary equipment. Oversize material can be recirculated back into the chamber or stockpiled via the integrated conveyor, providing flexibility and consistent product quality. With its improved material flow and production capabilities, the Finlay I-120RS is designed to meet the needs of modern recycling operations.

REQUEST A QUOTE

Fully Electric Power Option

Fully Electric Power Option

Designed with sustainability in mind, this electric impact crusher, sometimes known as a hybrid impact crusher, can operate via direct electric plug-in connection or its onboard genset, giving operators the flexibility to match site conditions. Electric operation reduces fuel usage, lowers emissions, and supports compliance with tightening environmental regulations. This I-120RS model is designed to meet the needs of modern construction projects, providing high productivity and improved material flow and production capabilities. By investing in electric powered equipment, users can benefit from energy-efficient and cost effective solutions that are generally more energy-efficient compared to diesel powered crushers.

REQUEST A QUOTE

Robust & Versatile Impact Chamber

Robust & Versatile Impact Chamber

At its core, the I-120RS electric impact crusher features a 1,150mm x 860mm (45” x 34”) horizontal impact chamber with variable rotor speeds for optimal shaping and reduction. The chamber’s direct drive system powers the feeder, offering superior energy efficiency, while hydraulic assist functions enable quick and safe configuration changes. This allows the impact crusher to handle a wide range of feed materials, from reinforced concrete to natural rock, making it ideal for recycling applications and designed to meet your needs.

REQUEST A QUOTEMobility, Safety & Operator Control

Despite its advanced features, this machine remains easy to transport and fast to set up, thanks to its compact footprint and hydraulically folding conveyors. A full-function remote control, ground-level service access, and large service doors improve daily safety and simplify maintenance. Intelligent load-sensing hydraulics and real-time monitoring provide operators with maximum control and confidence on-site, enhancing material flow and production capabilities while ensuring high productivity.

The I-120RS can be integrated into a recirculating system that can be quickly deployed for efficient recycling. This model is an electric powered option, offering benefits such as elimination of CO2 gas emissions and being generally more energy-efficient compared to diesel powered impact crushers. The direct drive system powers the feeder effectively, leading to high material reduction ratios and improved material flow and production.

Stay Updated with the Latest on the Finlay I-120RS Electric

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the I-120RS Electric.

Aggregate Solutions Built for Your Industry

Aggregates are essential in construction, infrastructure, and landscaping. They are used to build foundations for roads, bridges, and buildings, as well as in concrete and asphalt production. Construction aggregates also play a key role in drainage systems, water management, and environmental projects like erosion control and land reclamation. Their strength and versatility make them vital to numerous industries.

June 6, 2025

June 6, 2025