Finlay C-1540 Electric

Specifications

Finlay C-1540 electric cone crusher with flexible power options for quarrying & recycling

High-capacity electric cone crusher with flexible power options, on-board genset, or connected directly to the mains

The Finlay C-1540 electric cone crusher, delivers outstanding reduction and shape in a compact, fuel-efficient package. Powered by a direct electric drive system with the option of running from a mains connection or onboard genset, this cone crusher is designed to cut running costs, reduce emissions, and boost efficiency without compromising on performance. Its automatic tramp relief feature ensures that ‘auto-stop’ protects the cone from tramp material, while the automated metal detection system on feed enhances safety.

Engineered for quarrying, mining, construction, and recycling applications, the C-1540 is equipped with a proven 1,000mm (40”) cone chamber that provides excellent cubicity and consistent product quality. The purge system removes contaminants from the machine, reducing downtime by removing metal contaminants. With advanced control systems, fast setup, and built-in mobility, this efficient and productive machine ensures maximum uptime and versatility across a wide range of crushing environments.

Key features of the Finlay C-1540 electric cone crusher

Proven Cone Chamber Technology

Proven Cone Chamber Technology

At the heart of the C-1540 is its 1,000mm (40”) cone chamber with hydraulic closed side setting adjustment, automatic metal detection, and automatic tramp relief. This C-1540 cone crusher ensures excellent cubicity, consistent reduction, and protects the cone from tramp metal, effectively removing contaminants from the machine. The direct drive design provides high output capacity and reduces downtime by removing metal contaminants. Additionally, the purge system removes contaminants and enhances functionality and serviceability. With adjustable closed side settings, operators have precise control over product size, making it an efficient and productive machine for sized producers and contract crushing. The C-1540 is also choke-fed with an integrated level sensor for optimal performance.

REQUEST A QUOTE

Fully Electric Power System, with an On-Board Genset Power Option

Fully Electric Power System, with an On-Board Genset Power Option

The C-1540 cone crusher can operate via direct electric plug-in connection or an onboard genset, offering flexibility in varying site conditions. Electric operation reduces fuel costs, lowers emissions, and helps meet environmental compliance standards, making it ideal for urban and environmentally sensitive projects. The C-1540 direct drive cone crusher features high output capacity and efficient operation for crushing various materials. It includes a metal detection system on the feed that removes contaminants, ensuring detection and a purge system that reduces downtime. The automatic tramp relief and hydraulic closed side setting adjustment enhance maintenance ease and serviceability. It can be choke fed with an integrated level sensor, providing a high reduction ratio and optimal performance for sized producers and contract crushing. Additionally, the ‘auto-stop’ protects the cone from tramp material, ensuring the longevity of the C-1540 cone crusher.

REQUEST A QUOTE

Compact & Mobile Design

Compact & Mobile Design

Despite its high capacity, the C-1540 maintains a compact transport footprint with hydraulically folding conveyors for fast setup and relocation. This design ensures easier movement between job sites, quick commissioning, and reduced downtime, perfect for contractors who need mobility without sacrificing performance.

REQUEST A QUOTE

Intelligent Control & Operator Safety

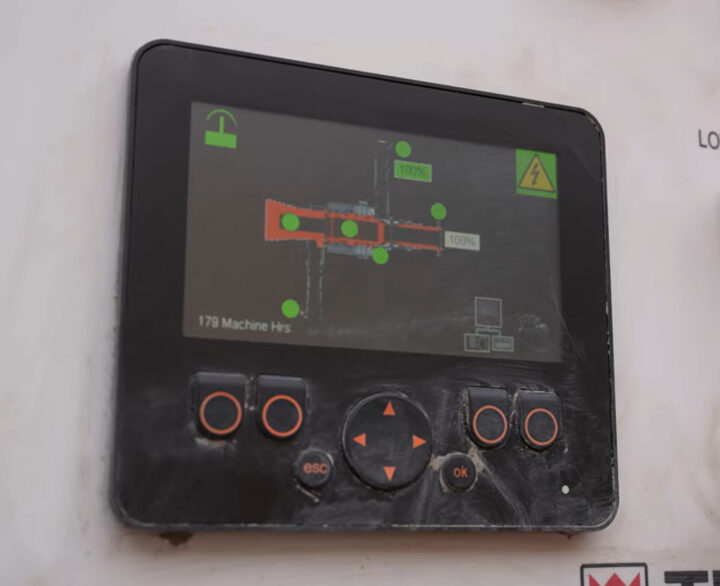

The C-1540 prioritises operational safety and ease of use. Features include a full-function remote control, ground-level maintenance access, and automated chamber monitoring. The crusher is equipped with load-sensing hydraulics and advanced diagnostics, enabling operators to maximise uptime while maintaining complete confidence in daily operations.

Stay Updated with the Latest on the Finlay C-1540 Electric

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the C-1540 Electric.

Aggregate Solutions Built for Your Industry

Aggregates are essential in construction, infrastructure, and landscaping. They are used to build foundations for roads, bridges, and buildings, as well as in concrete and asphalt production. Construction aggregates also play a key role in drainage systems, water management, and environmental projects like erosion control and land reclamation. Their strength and versatility make them vital to numerous industries.

June 6, 2025

June 6, 2025