Eggersmann TEUTON Z 50

Shredders

Specifications

Which Model Do You Need?

Eggersmann TEUTON Z 50: Single-shaft waste shredder

Long-life rotor system engineered for precision and durability

The Eggersmann TEUTON Z 50 is a universal shredder designed for stable and controlled material reduction across a wide range of applications. As a high-performance single-shaft shredder, it delivers exceptional versatility for both primary and secondary shredding stages. With a throughput of up to 95t/h, its mechanical architecture focuses on torque delivery, rotor mass and adaptive cutting clearance, ensuring strong performance over long service windows. The Z 50 maintains reliable throughput even when processing mixed or fibrous material streams and is engineered to limit wear in demanding recycling environments. Its robust drive and balanced cutting chamber make it ideal for first-stage volume reduction and secondary refinement.

TEUTON Z 50’s Key Features

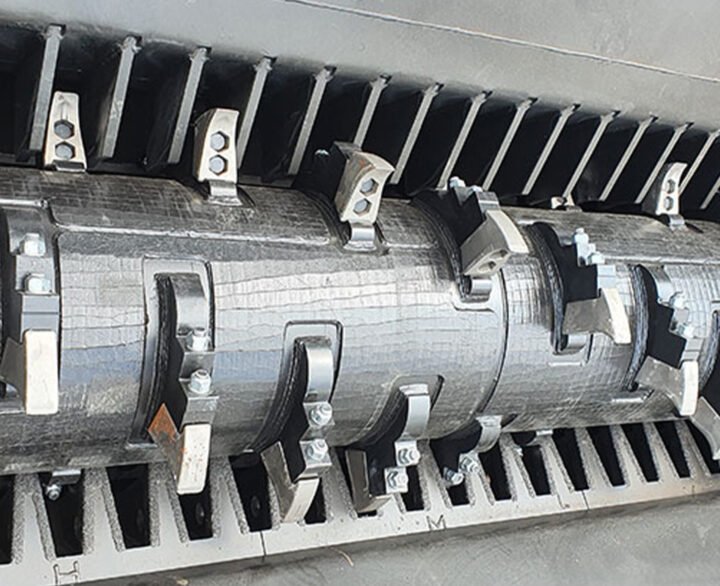

Marathon design single shaft

Marathon design single shaft

The TEUTON Z 50 features the Marathon-style single shaft: a heavy rotor engineered to resist deformation and heat accumulation over extended operation. Its mass provides high rotational stability and strong cutting force, while the shaft ensures consistent feed engagement. Equipped with durable rotor tools, the Z 50 delivers precise cutting and consistent material flow, making it a leading wood and green waste shredder for recycling operations.

REQUEST A QUOTE

Tool-free cutting gap adjustment

Tool-free cutting gap adjustment

The Z 50 provides tool-free adjustment of the cutting gap, enabling operators to control material output quickly and safely. Adjusting the clearance allows for coarser or finer reduction, improving performance when material type or density changes. No specialist tools are required, reducing setup time and keeping the machine productive. Gap optimisation also reduces unnecessary wear and improves efficiency, helping achieve the desired final grain size for downstream screening processes.

REQUEST A QUOTE

Reversible rotor

Reversible rotor

A reversible rotor design extends component life by distributing wear evenly across cutting surfaces. When rotation is reversed, fresh edges and teeth are engaged, maintaining cutting ability without manual blade changes. This system reduces downtime, supports minimal maintenance, and contributes to lower overall cost per tonne of processed material.

REQUEST A QUOTEMaterials it can process

The TEUTON Z 50 is capable of processing:

- Wood and green waste

- Municipal and commercial waste

- Biomass and compost feedstock

- Plastics, paper and other recyclables

The reversible shaft and adjustable cutting gap make the Z 50 suitable when operational demands vary. It is built on a robust chassis and powered by a high-performance diesel engine with low emission output, ensuring compliance with environmental standards. Material flow is supported by an integrated conveyor system for efficient discharge.

Stay Updated with the Latest News

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything.

Waste & Recycling Solutions Built for Your Industry

Looking for equipment tailored for the waste and recycling industry, including electric models for enhanced efficiency? At Molson Group, we provide a wide range of specialist machines designed to maximize efficiency in waste processing, material recovery, and recycling, including mobile options for various operating weights.. From shredders and screeners to electric material handlers and compactors, we have the right solutions to keep your work running smoothly. Explore our dedicated Waste & Recycling industry page to find the perfect equipment, complete with detailed info on specifications and capabilities, including our latest electric drive models.

January 16, 2026

January 16, 2026