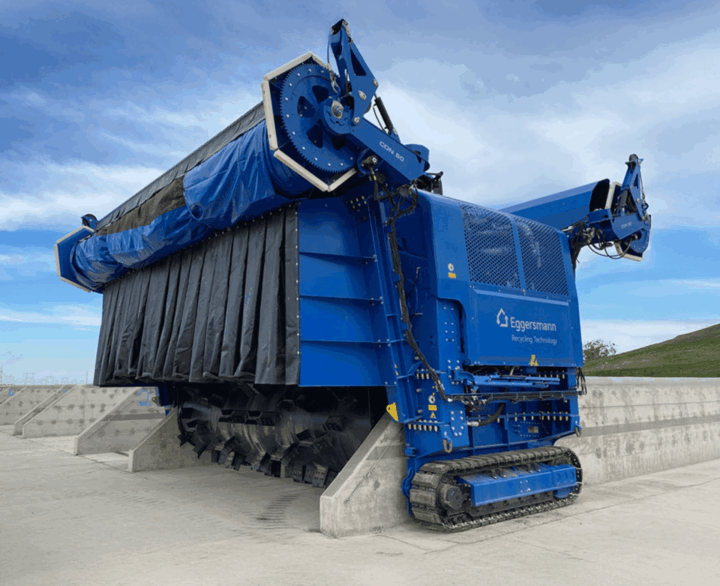

Eggersmann BACKHUS CON 60

Windrow Turner

Specifications

Eggersmann BACKHUS CON 60: Automated lane turner for membrane composting

Optimised decomposition with enclosed emission-controlled processing

The Eggersmann BACKHUS CON 60 is an automated compost turner designed for membrane composting systems and emission-controlled composting. Built for high process stability and controlled environmental impact, it manages windrow material within defined lanes while maintaining optimal oxygen transfer and moisture balance. With a throughput of up to 3,800 m³/h, a lane width of 6m, and a material height of 3.2m, the CON 60 is engineered for uniform turning in lanes over extended cycles, helping operators shorten maturation times, reduce odour escape, and maintain consistent compost quality. Its automated travel system ensures predictable progress along each lane, minimising labour involvement and preserving membrane cover integrity during the composting process.

BACKHUS CON 60’s Key Features

Automated turning with a membrane system

Automated turning with a membrane system

The CON 60 integrates directly with protective membrane structures used in regulated composting environments. Automated movement delivers consistent turning depth, allowing the windrow turner to oxygenate compost without opening or removing coverings. This approach stabilises composting temperature curves, reduces pathogens, and improves biological efficiency for composting and biological drying applications.

REQUEST A QUOTE

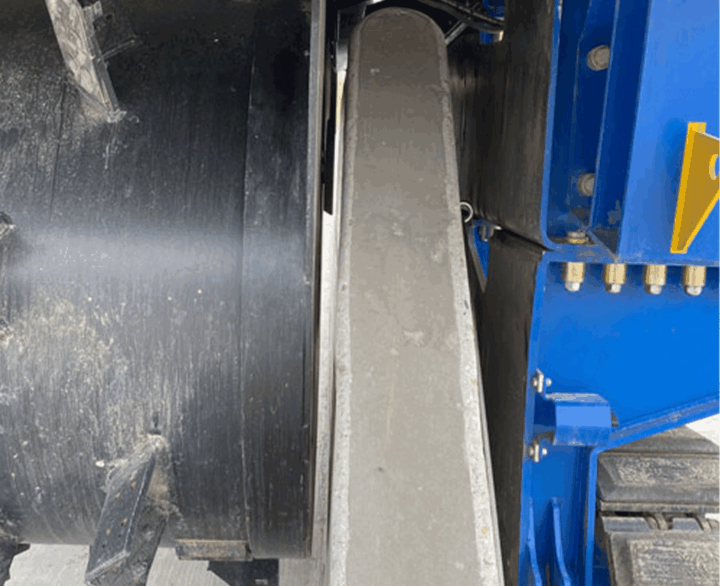

Closed system for emission control

Closed system for emission control

The membrane system helps capture moisture and volatile organic compounds, lowering emissions into the surrounding environment. Reprocessing occurs without exposing compost to wind, rain, or unwanted contaminants, supporting compliance with emission standards and improving overall environmental performance for municipal solid waste, municipal waste, and other waste and organic streams.

REQUEST A QUOTE

High throughput

High throughput

The CON 60 is configured for high throughput rates, making it suitable for operators processing large volumes of organics. The machine’s working width and turning geometry deliver effective lane agitation and accelerated composting cycles. Steady throughput reduces production bottlenecks and supports continuous plant efficiency in solid waste, green waste, and biological drying operations.

REQUEST A QUOTEMaterials it can process

The BACKHUS CON 60 is suitable for:

- Organic or green waste and biomass

- Agricultural manure compost

- Food waste and municipal solid waste

- Landscape waste and compost feedstock

Its lane-based format makes it appropriate for facilities using enclosed or emission-regulated composting systems.

Stay Updated with the Latest News

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything.

Waste & Recycling Solutions Built for Your Industry

Looking for equipment tailored for the waste and recycling industry, including electric models for enhanced efficiency? At Molson Group, we provide a wide range of specialist machines designed to maximize efficiency in waste processing, material recovery, and recycling, including mobile options for various operating weights.. From shredders and screeners to electric material handlers and compactors, we have the right solutions to keep your work running smoothly. Explore our dedicated Waste & Recycling industry page to find the perfect equipment, complete with detailed info on specifications and capabilities, including our latest electric drive models.

January 16, 2026

January 16, 2026