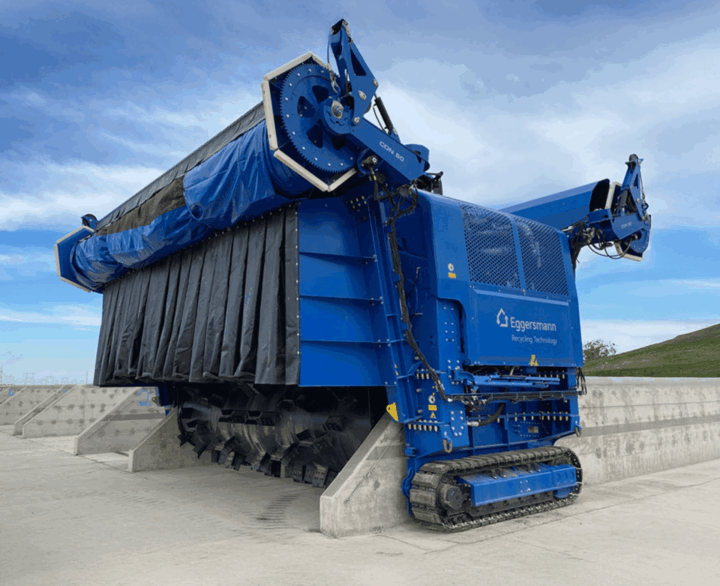

Eggersmann BACKHUS A 75

Windrow Turner

Specifications

The Eggersmann BACKHUS A 75: Largest compost windrow turner

High-output turning with direct rotor and operator visibility

The Eggersmann BACKHUS A 75 is a windrow turning machine and the most powerful model in the Backhus windrow turners range, designed for industrial-scale composting. Built for large windrow composting sites, this self-propelled windrow turner enables efficient aeration of the widest windrows while maintaining stable machine control. The A 75 offers substantial rotor power and advanced operator visibility, supporting rapid material homogenisation and dramatically reduced cycle times. This makes it appropriate where site footprint and throughput rates exceed the capability of smaller turners, ensuring efficient composting throughout the composting process.

The A 75 includes a robust cooling and engine system to maintain optimal operating temperatures during extended duty cycles, ensuring durability and consistent performance under heavy loads. With a turning capacity of up to 6,800 m³/h, a windrow width of 7.5m, and a windrow height of 3.3m, this model is engineered for the most demanding industrial-scale composting operations, delivering maximum efficiency and throughput.

BACKHUS A 75’s Key Features

Most powerful turning capacity

Most powerful turning capacity

With a turning capacity of up to 6,800 m³/h, a windrow width of 7.5m, and a windrow height of 3.3m, the A 75 delivers the strongest turning output of the range. Its rotor design provides strong penetration into dense material, supporting stable oxygen distribution and accelerated decomposition. Operators can adjust the speed of the rotors to optimise the turning process for different material types, including organic or green waste, and biomass, while maintaining low fuel consumption.

REQUEST A QUOTE

Rotor and drive control

Rotor and drive control

The model incorporates enhanced rotor and drive management to maintain traction and turning stability. These controls allow operators to match system performance to varying material densities, avoiding overstrain and protecting equipment components. Integrated Eggersmann Track Control, track clearers, and BACKHUS HD hose systems ensure reliability and precision during operation.

REQUEST A QUOTE

Panoramic cabin

Panoramic cabin

The machine’s panorama cabin offers excellent forward and lateral visibility. Clear sight lines improve turning accuracy, enhance machine placement, and deliver operator confidence during long processing pathways. The cabin provides maximum process control and can be operated manually when required. Optional features include side conveyor for efficient material discharge and a landfill version for specialised applications.

REQUEST A QUOTEMaterials it can process

The BACKHUS A 75 is suited to:

- Municipal organic or green waste

- Agricultural compost on large sites

- Landscaping and forestry residuals

- High-density compost and windrows

- Soil remediation projects

Its capability makes it appropriate for large composting enterprises and industrial organic processing.

Stay Updated with the Latest News

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything.

Waste & Recycling Solutions Built for Your Industry

Looking for equipment tailored for the waste and recycling industry, including electric models for enhanced efficiency? At Molson Group, we provide a wide range of specialist machines designed to maximize efficiency in waste processing, material recovery, and recycling, including mobile options for various operating weights.. From shredders and screeners to electric material handlers and compactors, we have the right solutions to keep your work running smoothly. Explore our dedicated Waste & Recycling industry page to find the perfect equipment, complete with detailed info on specifications and capabilities, including our latest electric drive models.

January 16, 2026

January 16, 2026