Sennebogen 835G

Port Handlers

Specifications

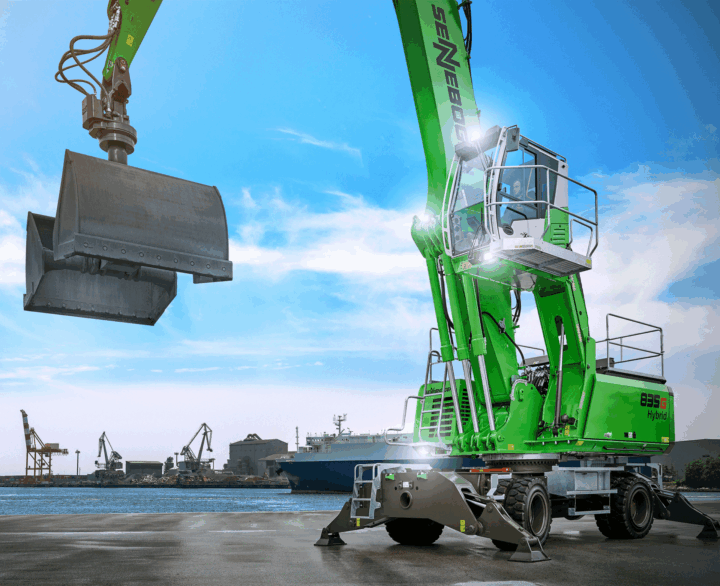

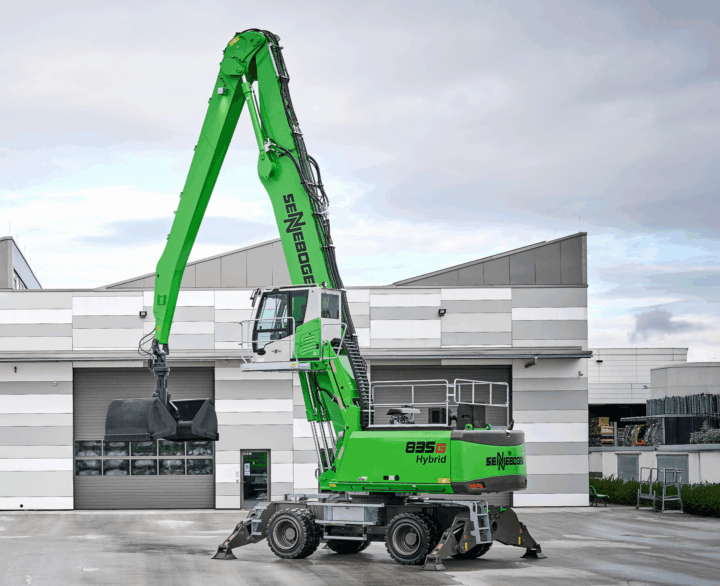

Sennebogen 835G Hybrid: The 20 m Reach Port Material Handler for Bulk and General Cargo Handling

The new Sennebogen 835G Hybrid: G Series High-Performance 20m reach Port Handler with Hybrid Energy Recovery

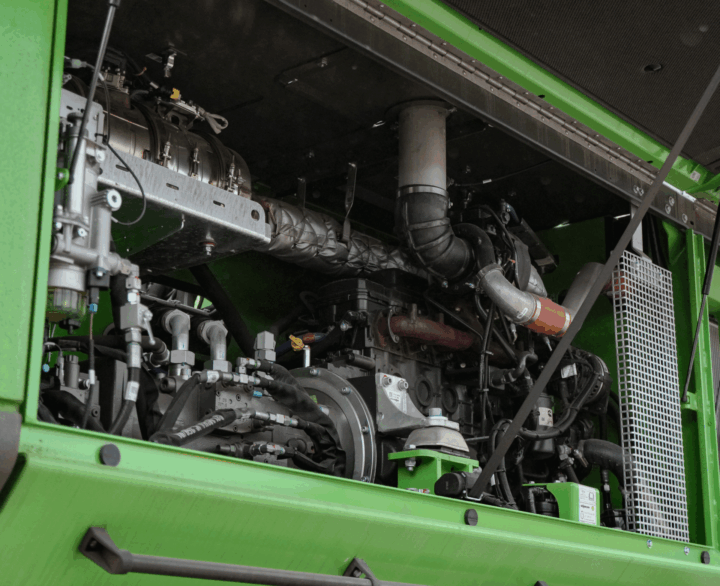

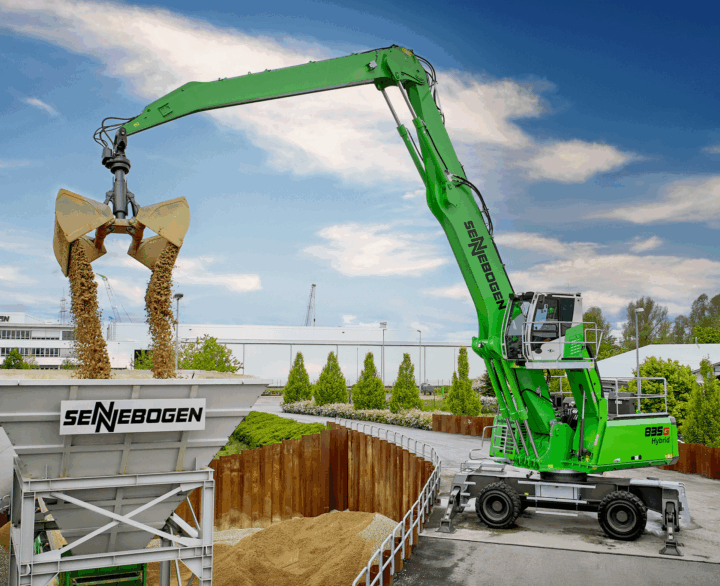

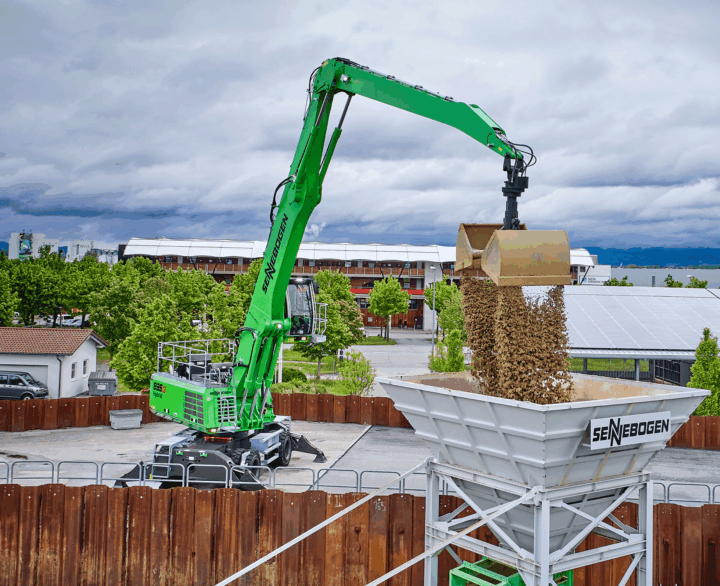

Purpose-built for heavy-duty port logistics, the Sennebogen 835G Hybrid port handler combines powerful performance with innovative green hybrid technology. With a reach of up to 20 metres and an operating weight of 47.3 tonnes, this robust machine is engineered to handle bulk goods, general cargo, timber, and containers while delivering significant fuel savings. Powered by a Stage V Cummins B6.7 Diesel Engine with Sennebogen’s green hybrid energy recovery system, the 835G Hybrid sets new standards for efficient port operations, offering strong performance with lower emissions and operating costs. Electric drive options are also available to suit low-emission port strategies.

Whether you choose diesel or electric, the Sennebogen 835G Hybrid can be configured to align with your port’s energy goals. Designed for high-output terminals and extended duty cycles, it keeps your operations moving efficiently and economically. Its completely redesigned machine design and reworked hydraulics improve load handling across port-side operations and vessel loading, enhancing movement and speed for scrap and timber handling. The mobile undercarriage and elevating cab provide maximum operator comfort and visibility, ensuring precise handling in demanding material handling environments.

Key Features of the Sennebogen 835G Hybrid

The Sennebogen 835G hybrid port handler sets new standards with its innovative green hybrid energy recovery system, which stores energy when lowering the boom and reuses it during lifting, resulting in up to a 30% reduction in fuel consumption. This 835G hybrid innovation, paired with rugged construction and low-maintenance components, makes it ideal for demanding port operations.

Choose between a mobile undercarriage for agile movement across the yard or a crawler system for optimal stability along quay edges or soft ground. Whatever the configuration, the Sennebogen 835G hybrid delivers precise accuracy, balance, and durability under load, making it an efficient choice for timber handling, recycling and bulk material handling.

Operator Comfort with the G-Series Maxcab

Operator Comfort with the G-Series Maxcab

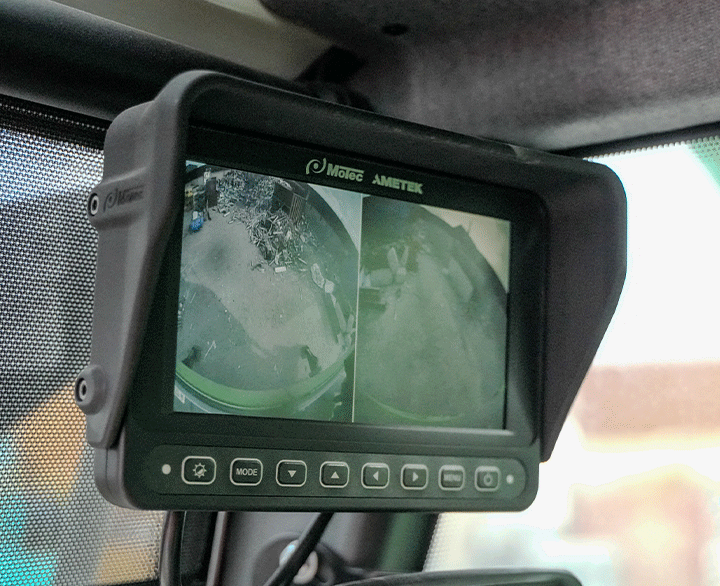

Inside the Maxcab of the Sennebogen 835G Hybrid port handler, operators benefit from a workspace built for long shifts and harsh environments. Joystick steering, a heated air-suspended seat, and wide, panoramic views all contribute to enhanced efficiency and concentration. Optional bulletproof glass, safety guards, and full 360° camera systems further improve safety and visibility during demanding port operations.

REQUEST A QUOTE

Performance and Efficiency for Port Operations

Performance and Efficiency for Port Operations

As part of the G series, the Sennebogen 835G Hybrid also introduces optimised hydraulics and a streamlined machine design that sets new standards for efficient port handling. Maintenance is simplified with centralised access points, helping reduce downtime while increasing operational productivity. This innovative material handler, featuring recuperation technology, combines a green hybrid energy recovery system, ensuring maximum fuel efficiency and up to a 50% reduction in operating costs. The 835G Hybrid is designed for precise and fast movement, making it ideal for timber handling and recycling operations.

REQUEST A QUOTE

Smart Technology to Power Smarter Port Workflows

Smart Technology to Power Smarter Port Workflows

At its core is the SENCON control system with a 10″ touchscreen display for intuitive operation and diagnostics. Operators can monitor performance, adjust hydraulic flows for various attachments, and fine-tune machine settings, all from the comfort of the cab. Whether you’re using clamshell buckets, timber grabs, or custom port tools, the Sennebogen 835G hybrid port handler gives operators complete control to stay productive. The 835G hybrid model is designed for demanding material handling in port operations, ensuring efficient movement and precise operation. With its innovative green hybrid energy recovery system, this material handler not only elevates performance but also reduces fuel consumption and operating costs by up to 50%. The 835 G hybrid sets new standards for efficient port handling, making it an ideal choice for timber handling, recycling, and other port activities.

REQUEST A QUOTEPrioritising Safety in Busy Work Zones

The new Sennebogen 830G waste material handler isn’t just powerful; it’s designed with operator safety in mind. From its excellent all-around visibility to integrated safety systems, such as pipe burst protection and optional camera setups, this material handler is built to provide peace of mind during waste management. Whether navigating tight yards or handling unpredictable material, this versatile material handler supports a safe and efficient working environment. The 830G is part of the new G-series, known for its exceptional material handling capabilities.

Stay Updated with the Latest on the Sennebogen 835G

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the 835G.

Ready for the Demands of Port Terminals and Harbours

Built for precision handling, fast cycles, and continuous throughput, the Sennebogen 835G Hybrid excels in busy port terminals. Its energy-saving hybrid system, flexible undercarriage options, and operator-first design make it the go-to solution for those seeking to increase capacity while reducing costs and emissions.

November 24, 2025

November 24, 2025