Sennebogen 835G

Scrap Handlers

Specifications

Sennebogen 835G Hybrid: The 20m Reach Scrap Material Handler for Heavy-Duty Scrap Recycling

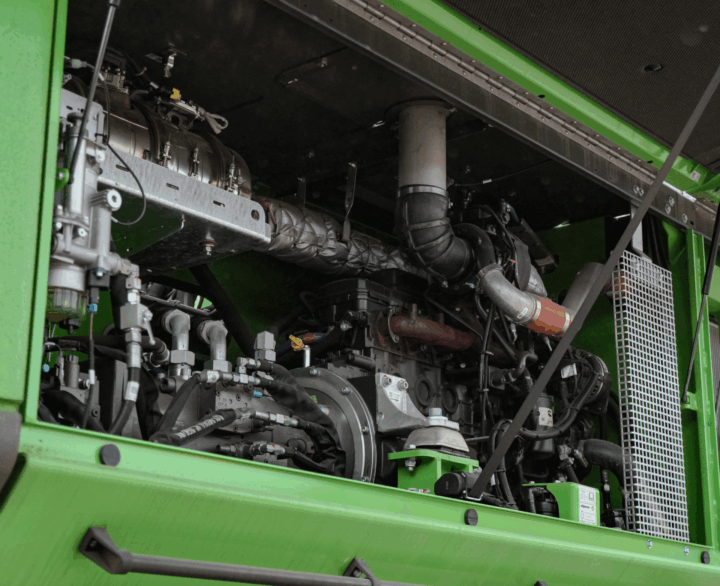

Purpose-built for demanding material handling, the Sennebogen 835G Hybrid material handler combines powerful performance with cutting-edge green hybrid technology. With a reach of up to 20 metres and an operating weight of 47.3 tonnes, this robust machine design is engineered to tackle the most challenging recycling environments while significantly lowering fuel consumption. With a Stage V Cummins B6.7 Diesel Engine featuring Sennebogen’s innovative green hybrid energy recovery system, the 835G Hybrid delivers maximum power with reduced operating costs and emissions. It is also available with electric drive options.

Whether diesel-powered or electric, the 835G Hybrid can be optimised to align with your site’s energy strategy. From high-output yards to long-loading cycles, this machine is built to work harder for longer, with less impact on your bottom line. The equipment lengths and hydraulics have been completely reworked to enhance the efficiency of the material handler, ensuring that it meets the demands of applications in scrap and timber handling as well as port operations.

The new Sennebogen 835G Hybrid: G Series High-Performance 20m reach Scrap Handler with Hybrid Energy Recovery

Key Features of the Sennebogen 835G Hybrid

Operator Comfort Designed for Productivity with the Maxcab

Operator Comfort Designed for Productivity with the Maxcab

The spacious Maxcab comfort cab of the 835G hybrid scrap handler is designed with long shifts in mind. Featuring joystick controls, an air-suspended heated seat, and panoramic visibility, it helps operators stay focused and alert throughout the day. Optional bulletproof glass, protective guards, and 360-degree camera systems enhance on-site safety, ensuring operator comfort during demanding applications involving the handling of recycled metals.

REQUEST A QUOTE

Performance Meets Sustainability with the 835G Scrap Material Handler

Performance Meets Sustainability with the 835G Scrap Material Handler

This new Sennebogen model is part of the G series and features an innovative green hybrid energy recovery system, enabling energy efficiency and reducing operating costs by up to 50 %. The hydraulics have been completely reworked, optimising the efficiency of the material handler for both scrap handling and port operations.

With a clearly structured machine design and central maintenance features, the 835G hybrid sets new standards in material handling. The hybrid system enhances performance, while the hydraulic cylinder and hose systems are designed for maximum performance under rigorous conditions.

REQUEST A QUOTE

Advanced Technology for Smarter Workflows

Advanced Technology for Smarter Workflows

At the heart of the 835G hybrid is the SENCON control system with a 10” touchscreen interface, delivering intuitive scrap handler control and diagnostics. Whether tracking performance, configuring attachments like orange peel grabs, or adjusting hydraulic flows, operators have the tools they need at their fingertips to stay productive and in control. This new Sennebogen model is designed to optimise operating costs and improve the efficiency of the scrap handler in demanding recycled metal handling applications.

REQUEST A QUOTEReady for the Toughest Scrap Handling Challenges

Engineered for heavy lifting, precision placement, and bulk sorting, the Sennebogen 835G Hybrid is ideal for fast-paced scrap yards, export terminals, and material recovery facilities. Its energy-efficient hybrid system, strong undercarriage options, and flexible configuration make it the go-to choice for those seeking both performance and sustainability.

Stay Updated with the Latest on the Sennebogen 835G

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the 835G.

A Waste Handler That Works as Hard as You Do

Find out how the new Sennebogen 835G can enhance your material handling processes in waste management. This waste material handler is equipped with a Sencon control system and a 10-inch touch display for efficient operation. The Sennebogen 835G sets new standards in waste and recycling handling, featuring a Maxcab comfort cab for driver comfort and a loading and unloading capability that enables loading recycling material onto trucks. Discover how the new 835G series can make your daily work more efficient. Visit the Molson site for machine specs, latest news, and real customer stories.

November 24, 2025

November 24, 2025