Sennebogen 830G

Scrap Handlers

Specifications

The New Sennebogen 830G: A Scrap Handler for Demanding Metal Recycling Applications

A robust 17 m reach material handler for scrap recycling handling

Engineered to thrive in the most demanding scrap handling environments, the new Sennebogen 830G delivers outstanding reach, power, and flexibility. With a maximum reach of 17 m and an operating weight of 41.3 tonnes, this machine is designed to tackle the most demanding tasks in scrap handling and recycling. Whether you need a diesel-powered machine with Stage V emissions compliance or an all-electric option, the Sennebogen 830G can be tailored to your operational and sustainability needs.

Optimised for non-stop operation, the 830G is equipped with the advanced G-series hydraulic system, offering powerful performance and versatility. You can choose between a wheeled or crawler undercarriage to match the specific conditions of your job site. With its elevated Maxcab and superior visibility, operators can work with confidence and comfort. The modular design allows for compatibility with a range of attachments, making the 830G adaptable to various scrap handling tasks. Designed for efficiency, this machine ensures minimal downtime and long-term cost savings.

Key Features of the Sennebogen 830G

The Sennebogen 830G material handler has been developed with cost-efficiency at the forefront. Featuring a powerful Cummins B6.7 Stage V diesel engine or an electric drive option, it helps reduce fuel consumption and emissions, contributing to a more sustainable operation. The 830G’s durable frame, heavy-duty components, and precision-engineered hydraulic system ensure that the machine delivers reliable performance with minimal maintenance needs. From sorting scrap to loading materials, the 830G keeps your operations running smoothly while keeping operational costs in check.

Choose between a mobile undercarriage for superior mobility or a crawler system for added stability and traction. The tracked option is especially beneficial for navigating uneven ground, while the mobile undercarriage enhances manoeuvrability on smoother surfaces. This flexibility ensures that the Sennebogen 830G can meet the needs of various scrap handling applications, from tight yard spaces to more rugged scrap yards.

Lower Operating Costs, Higher Performance

Lower Operating Costs, Higher Performance

The G-series enhancements on the Sennebogen 830G include an ergonomic Maxcab comfort cab, a more efficient hydraulic circuit for precise material handling, and compatibility with an extensive range of grabs and attachments, such as the orange peel grab. Whether it’s for feeding shredders, loading containers, or sorting scrap, the 830G provides the strength and precision you need for heavy-duty tasks.

REQUEST A QUOTE

Enhanced Efficiency and Control

Enhanced Efficiency and Control

The Sennebogen 830G is equipped with a load-sensing hydraulic system that directs power to where it’s needed most, ensuring maximum efficiency with no wasted energy. This system helps improve cycle times, reducing fuel consumption while maintaining top-level output. With a reach of 17 m and an operating weight that’s ideal for mid- to heavy-duty scrap handling tasks, the Sennebogen 830G is built to boost productivity without compromising on precision.

REQUEST A QUOTE

The G Series Maxcab Comfort for Long Shifts

The G Series Maxcab Comfort for Long Shifts

For operators working long hours, the spacious Maxcab offers a climate-controlled environment that prioritises comfort. The elevated position of the cab provides operators with a clear view of the entire work area, while intuitive joystick controls and an air-suspended, heated seat help reduce fatigue. This ergonomic design helps enhance productivity and safety, ensuring that operators can perform at their best throughout their shift.

REQUEST A QUOTEPrioritising Safety in Dynamic Work Zones

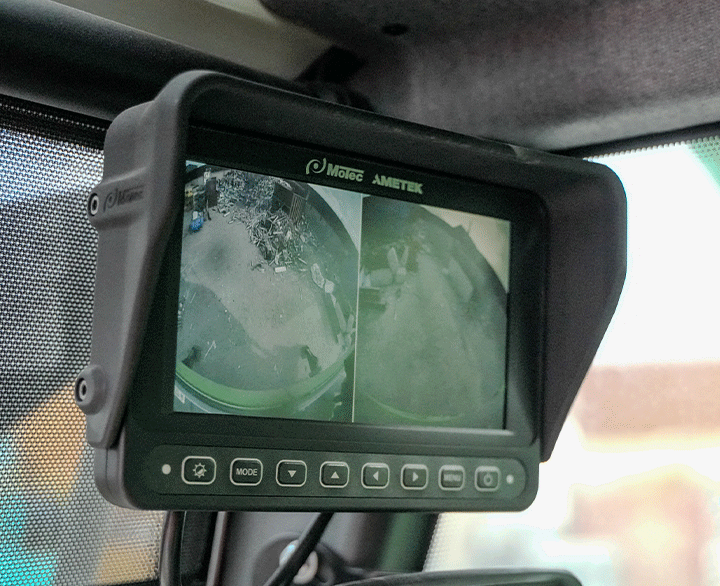

The Sennebogen 830G material handler isn’t just about performance; it’s built with operator safety in mind. The machine offers excellent all-around visibility and is equipped with integrated safety systems like pipe burst protection and optional cameras. These features ensure safe operation in unpredictable environments, whether on busy scrap yards or working with challenging materials. The 830G is part of the G-series, renowned for its top-tier material handling capabilities, providing safety and efficiency across demanding operations.

Stay Updated with the Latest on the Sennebogen 830G

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the 830G.

A Scrap Handler Built for Tough Jobs

Discover how the Sennebogen 830G can optimise your scrap handling processes. Equipped with the Sencon control system and a 10-inch touchscreen display, this material handler ensures seamless and efficient operation. With a spacious Maxcab, advanced hydraulics, and the ability to load scrap material onto trucks, the 830G streamlines material handling in scrap yards and recycling operations. Visit the Molson site for machine specs, latest news, and real customer stories.

November 24, 2025

November 24, 2025