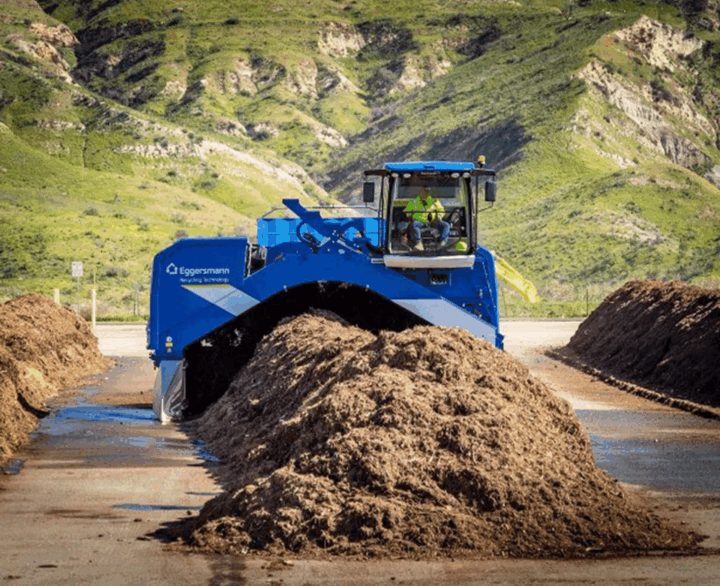

Eggersmann BACKHUS A 50 / A 55

Windrow Turner

Specifications

Eggersmann A 50 / A 55 industrial compost turners for large windrow capacity

Advanced monitoring, high rotor power and dependable performance

The Eggersmann BACKHUS A 50 / A 55 are high-capacity compost turners designed for industrial-scale windrow composting. These BACKHUS turners offer robust rotor capability and advanced operator aids, helping maintain ideal composting conditions along the row. With a throughput of up to 4,500 m³/h, a windrow width of 5.5m, and a windrow height of 2.5m, the A 50 / A 55 are built for continuous flow operations, combining turning efficiency with precise handling to accelerate compost maturity and improve material quality. As part of the BACKHUS triangular windrow turners range, these machines are engineered for durability and high performance in demanding environments.

BACKHUS A 50 / A 55’s Key Features

Height-adjustable and automatically reversible rotor

Height-adjustable and automatically reversible rotor

The adjustable rotor allows material engagement at varying depths, enabling efficient turning of dense or matted windrows. The automatically reversible configuration distributes wear evenly, improving the rotor’s service life and reducing component replacement frequency. Operators can also control the speed of the rotors for optimal aeration and mixing during windrow composting.

REQUEST A QUOTE

12-inch display screen

12-inch display screen

The operator interface features a 12-inch display inside the cabin, providing clear information on performance, diagnostics, and control inputs. This increases process transparency, improves parameter adjustments, and enables responsive decision-making during turning operations. The advanced display contributes to more consistent compost production and can be operated manually for full control.

REQUEST A QUOTE

Sophisticated cooling system

Sophisticated cooling system

The A 50 / A 55 integrate a cooling and engine system engineered to stabilise temperature during extended operation. By preventing heat buildup, the system protects hydraulic and drive components, promoting machine longevity and maintaining consistent torque delivery. The machines also include BACKHUS HD hose for hydraulic reliability and Eggersmann Track Control for precise movement in challenging terrain.

REQUEST A QUOTEMaterials it can process

The BACKHUS A 50 / A 55 can handle:

- Composting of green and organic waste

- Agricultural organics and green and organic goods

- Manure-based composting operations

- Large windrow processing cycles

Additional features include side conveyor options for efficient material discharge and a landfill version for specialised applications. These turners for windrow composting provide access to all components for maintenance, ensuring they remain easy to maintain even under heavy-duty conditions.

Stay Updated with the Latest News

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything.

Waste & Recycling Solutions Built for Your Industry

Looking for equipment tailored for the waste and recycling industry, including electric models for enhanced efficiency? At Molson Group, we provide a wide range of specialist machines designed to maximize efficiency in waste processing, material recovery, and recycling, including mobile options for various operating weights.. From shredders and screeners to electric material handlers and compactors, we have the right solutions to keep your work running smoothly. Explore our dedicated Waste & Recycling industry page to find the perfect equipment, complete with detailed info on specifications and capabilities, including our latest electric drive models.

January 16, 2026

January 16, 2026