Sennebogen 824G

Scrap Handlers

Specifications

Sennebogen 824G 12m Reach Scrap Handler: The Ultimate Solution for Metal Recycling and Scrap Solutions

Your 12m reach scrap handler for scrap handling and recycling applications

The SENNEBOGEN 824G is a robust and versatile scrap handler, specifically designed to meet the demanding requirements of scrap yards and recycling operations. With a reach of 12 meters and an operating weight of up to 27.1 tonnes, it strikes the perfect balance of power, efficiency, and precision. Designed with advanced G-series hydraulics and available in both diesel and electric power options, the 824G ensures peak performance while minimising fuel consumption or emissions, depending on your chosen power option.

The SENNEBOGEN 824G is available in both wheeled and crawler versions, providing flexibility to suit various site conditions. Whether you’re loading, sorting, or moving heavy scrap materials, the wheeled undercarriage provides excellent stability on uneven ground, while the crawler version is ideal for more demanding environments that require extra traction. Both versions ensure the durability and reliability needed to handle heavy-duty tasks. The elevated cab offers operators a clear, commanding view of the work area, enhancing control and safety. Easy maintenance access through multiple service points helps reduce downtime and keep operating costs low. Designed for scrap handling and metal recovery, the 824G is the perfect choice for waste management and material processing operations, offering maximum efficiency and a long service life.

Key Features of the Sennebogen 824G Scrap Handler

The SENNEBOGEN 824G stands out for its robust design and efficient operation. Powered by a Cummins B4.5 Stage V diesel engine delivering 123 kW, or available with a tethered electric motor option, it combines strong performance with reduced emissions or even zero emissions for environmentally-conscious operations. The load-sensing hydraulic system delivers power only when needed, improving fuel efficiency while ensuring smooth, responsive control for maximum productivity.

Operators benefit from the spacious, elevated cab, which provides excellent visibility, ergonomic controls, and a climate-controlled workspace, ideal for long shifts in demanding environments. Its modular design allows configuration with a range of attachments to meet the specific needs of handling metals, scrap, and other recovered materials, delivering versatility and consistent performance across a variety of tasks.

Low Operating Machine Costs

Low Operating Machine Costs

The SENNEBOGEN 824G stands out for its robust design and efficient operation. Powered by a Cummins B4.5 Stage V diesel engine delivering 123 kW, or available with a tethered electric motor option, it combines strong performance with reduced emissions or even zero emissions for environmentally-conscious operations. The load-sensing hydraulic system delivers power only when needed, improving fuel efficiency while ensuring smooth, responsive control for maximum productivity.

Operators benefit from the spacious, elevated cab, which provides excellent visibility, ergonomic controls, and a climate-controlled workspace, ideal for long shifts in demanding environments. Its modular design allows configuration with a range of attachments to meet the specific needs of handling metals, scrap, and other recovered materials, delivering versatility and consistent performance across a variety of tasks.

REQUEST A QUOTE

Intelligent Hydraulic System for Precise Scrap Handling

Intelligent Hydraulic System for Precise Scrap Handling

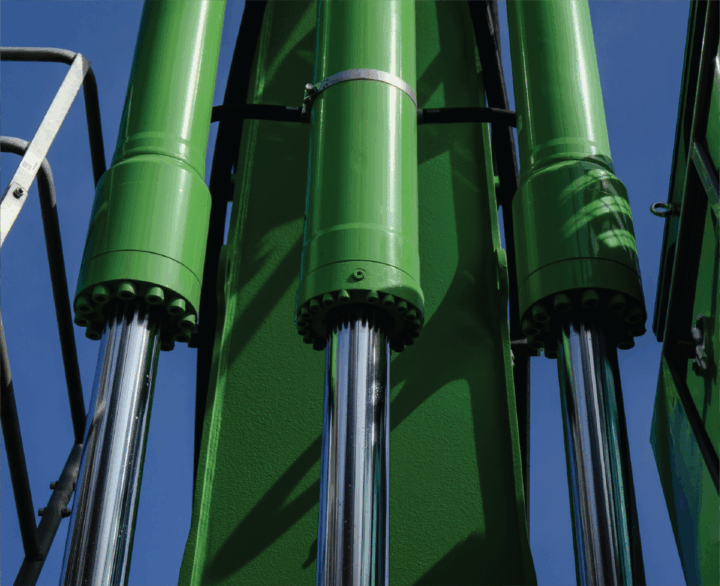

SENNEBOGEN’s advanced G-series hydraulics provide the precision and power needed for efficient scrap handling and recycling. The Sennebogen 824G scrap handler features a load-sensing system that optimises fuel consumption while reducing operating costs. Its robust mobile undercarriage ensures maximum stability in demanding scrap yard conditions, with 12 m reach and impressive load capacities for handling bulky, heavy recycling material. The new Sennebogen 824G is designed for material handling in recycling and scrap processing, making it an ideal choice for waste management and recycling applications. With its robust components and long service life, this material handler for recycling is perfect for continuous use.

REQUEST A QUOTE

Maxcab: Designed for Operator Comfort in Demanding Environments

Maxcab: Designed for Operator Comfort in Demanding Environments

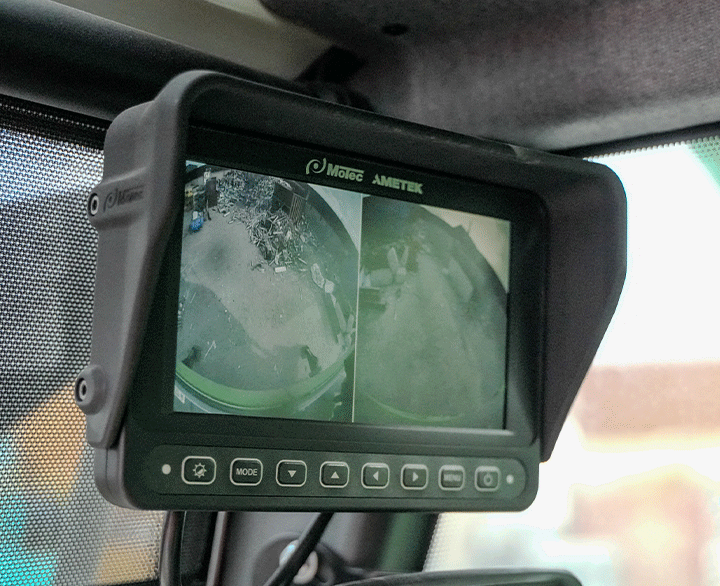

The SENNEBOGEN 824G features the G Series Maxcab, designed for optimal operator comfort and productivity in the most demanding scrap handling and recycling environments. The cab provides superior visibility, enabling operators to maintain a clear view of the work area, which is particularly crucial in busy, cluttered environments. Ergonomic joysticks and an air-suspension seat ensure long-shift comfort and precise control. For enhanced safety, the cab comes equipped with integrated safety cameras, and its elevating design allows operators to adjust their position for the best view, enhancing both visibility and overall control during operation. This design ensures operators stay comfortable, safe, and focused, even in the toughest conditions.

REQUEST A QUOTESafety and Reliability at the Core

With features such as an elevating cab and a mobile undercarriage, the SENNEBOGEN 824G scrap handler provides excellent reach of 12 m and stability. This robust machine is designed for recycling and scrap handling, ensuring low fuel consumption or zero emissions (with the electric drive option) and high load capacities, making it ideal for continuous use in scrap management and material handling. The new SENNEBOGEN 824G series offers maximum efficiency and performance, making it ideal for demanding continuous operations in scrap yards and recycling material facilities.

Stay Updated with the Latest on the Sennebogen 824G

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the 824G.

Scrap Handling Solutions Built for Your Industry

Discover how the SENNEBOGEN 824G scrap handler can optimise your scrap handling and recycling operations. This versatile handler, available in both diesel and electric power options, combines a mobile undercarriage, low fuel consumption (or zero emissions with the electric option), and maximum efficiency for demanding work environments. Visit Molson’s site for customer stories, product highlights, and the latest news on the SENNEBOGEN 824G and other material handling machines.

January 16, 2026

January 16, 2026