Eggersmann BACKHUS CON 100

Windrow Turner

Specifications

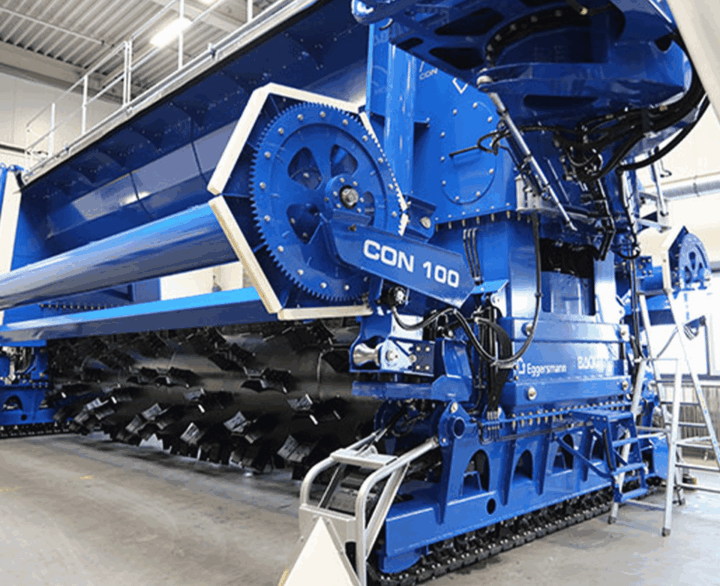

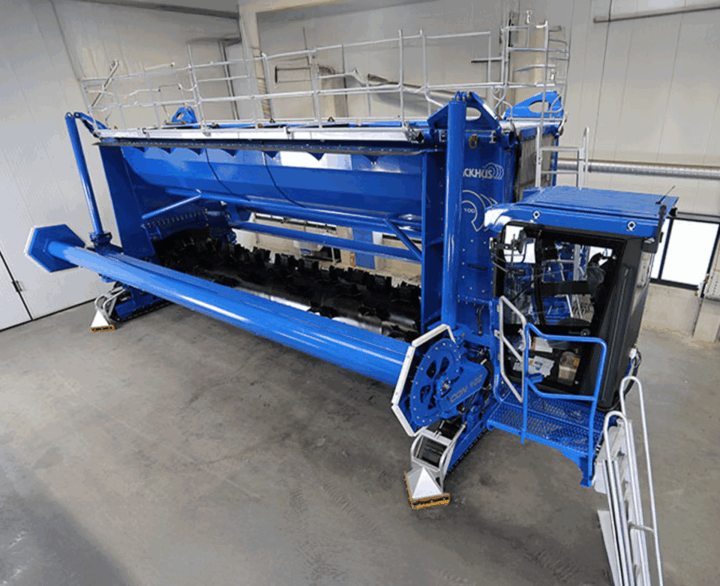

Eggersmann BACKHUS CON 100: Automated lane windrow turner with integrated membrane

Large windrow coverage and controlled emission composting

The Eggersmann BACKHUS CON 100 is an automated compost turner designed for membrane composting using the Convaero system. Built for large-scale industrial operations, it supports composting and biological drying of household waste and organic waste, commercial waste, and biomass. With a throughput of up to 7,200 m³/h, a lane width of 10m, and a material height of 3.2m, the CON 100 is engineered for advanced enclosed composting, maintaining a high level of oxygen exchange while strictly controlling emissions and heat retention. Its large working width and automated navigation enable consistent compost handling with minimal labour input, supporting long-cycle industrial operations with short processing time and efficient aeration and process control.

BACKHUS CON 100’s Key Features

Automated lane management with an integrated membrane

Automated lane management with an integrated membrane

The CON 100 autonomously follows lane walls, maintaining hydraulic and rotor positioning while preserving the membrane cover. This enables controlled decomposition without surface disruption and reduces the risk of aerobic failure. Integrated winding and unwinding functionality ensures the Convaero membrane remains secure during the drying process, even with high moisture content. Operators benefit from predictable compost performance and reduced on-site intervention.

REQUEST A QUOTE

Closed system technology

Closed system technology

The closed composting environment captures evaporative moisture and emissions, creating conditions where temperature elevation remains stable and decomposition accelerates. By minimising exposure to external weather conditions, the compost environment remains consistent and efficient, staying low on emissions while supporting biological drying of household waste and municipal solid waste streams.

REQUEST A QUOTE

6m max lane width

6m max lane width

The machine is capable of working across lane widths up to 6 metres, supporting high-density composting with minimal pass frequency. Larger compost volumes are turned effectively, increasing productive output across each processing lane. Operators can adjust the speed of the rotors for maximum efficiency during the turning process, ensuring optimal aeration and homogenisation.

REQUEST A QUOTEMaterials it can process

The BACKHUS CON 100 is designed to handle:

- Household waste and organic waste

- Large-scale agricultural and dairy residues

- Landscape waste and biomass compost

- Centralised organic recycling operations

Its large working width is well suited to industrial compost plants, and Eggersmann provides full supply and commissioning for seamless integration. Optional features include shredded waste to the conveyor for streamlined material flow and enhanced aeration and membrane cover performance.

Stay Updated with the Latest News

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything.

Waste & Recycling Solutions Built for Your Industry

Looking for equipment tailored for the waste and recycling industry, including electric models for enhanced efficiency? At Molson Group, we provide a wide range of specialist machines designed to maximize efficiency in waste processing, material recovery, and recycling, including mobile options for various operating weights.. From shredders and screeners to electric material handlers and compactors, we have the right solutions to keep your work running smoothly. Explore our dedicated Waste & Recycling industry page to find the perfect equipment, complete with detailed info on specifications and capabilities, including our latest electric drive models.

February 16, 2026

February 16, 2026