Eggersmann BACKHUS A 30

Windrow Turner

Specifications

Eggersmann BACKHUS A 30: Compact compost windrow turner

Mobile windrow turning with low fuel usage and controlled material blending

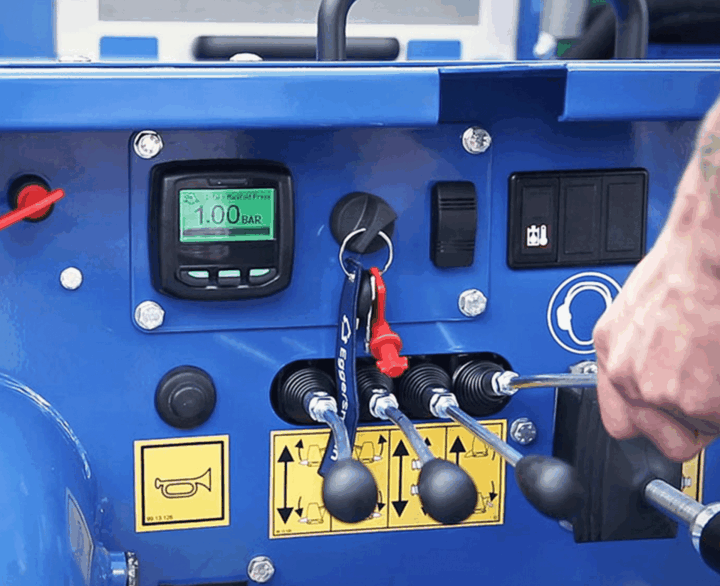

The Eggersmann BACKHUS A 30 is a compact, self-propelled windrow turner engineered for sites requiring reliable windrow management in a small footprint. Designed for stability and ease of operation, the A 30 maintains consistent turning performance while keeping fuel consumption low. With a turning capacity of 700 m³/h, a windrow width of 3.0m, and a windrow height of 1.3m, its chassis and rotor configuration enable efficient aeration and homogenisation, increasing compost material quality and accelerating biological processing. Lightweight construction and intuitive controls make it suitable for composting facilities, agricultural businesses, and operators beginning organic material processing in recycling and composting applications.

BACKHUS A 30’s Key Features

Self-propelled machine

Self-propelled machine

The BACKHUS A 30 operates as a self-contained unit, allowing full mobility without additional towing equipment. This independence gives operators flexibility in windrow placement and layout design, enabling smooth material transitions across the composting site. The self-drive system reduces labour dependency and streamlines repositioning between rows. For added versatility, the machine can be mounted on a trailer for transport between sites.

REQUEST A QUOTE

3m wide, 700 m³/h turning capacity

3m wide, 700 m³/h turning capacity

The A 30 delivers a turning capacity of up to 700 cubic metres per hour, enabling steady progress along windrows without recurring stoppage. This output is well-suited to smaller facilities and helps maintain consistent biological conditions within compost piles. By reliably mixing material, oxygen levels remain high, temperature increases are controlled, and decomposition progresses efficiently.

REQUEST A QUOTE

Automatic ground contour

Automatic ground contour

The machine automatically adapts to soil unevenness during operation. Ground contour following helps maintain consistent turning depth and stable machine positioning. This prevents rotor overload, protects the windrow shape, and allows operators to work across variable terrain without constant manual adjustments. The rotor system is reversible, improving wear distribution and extending component life.

REQUEST A QUOTEMaterials it can process

The BACKHUS A 30 is designed for:

- Green waste and garden cuttings

- Animal manures and agricultural residues

- Food waste and pre-composted organics

- Landscaping waste and compost feedstock

Its compact design makes it suitable for operators with limited space or local compost sites.

Stay Updated with the Latest News

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything.

Waste & Recycling Solutions Built for Your Industry

Looking for equipment tailored for the waste and recycling industry, including electric models for enhanced efficiency? At Molson Group, we provide a wide range of specialist machines designed to maximize efficiency in waste processing, material recovery, and recycling, including mobile options for various operating weights.. From shredders and screeners to electric material handlers and compactors, we have the right solutions to keep your work running smoothly. Explore our dedicated Waste & Recycling industry page to find the perfect equipment, complete with detailed info on specifications and capabilities, including our latest electric drive models.

February 27, 2026

February 27, 2026