Sennebogen 826G

Waste Handlers

Specifications

Sennebogen 826G: The 13m Reach Material Handler for Your Waste and Recycling Applications

The Sennebogen 826G: A Powerful & Versatile Waste Material Handler for Recycling Applications

The 826G is a versatile and durable material handler, specifically designed to meet the demands of recycling applications. With an impressive 13m reach and an operating weight of up to 31.7 tonnes, it delivers the perfect combination of power and efficiency for heavy-duty tasks. Available with either a Stage V diesel engine or a tethered emission electric drive, the Sennebogen 826G offers the flexibility to adapt to various environmental and operational needs, making it a top choice for waste and recycling facilities seeking to enhance their sustainability and performance.

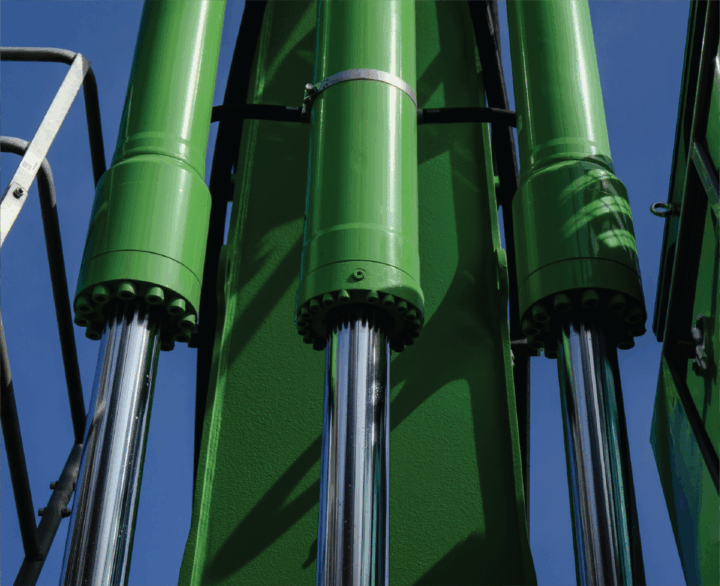

Built for continuous operation, the 826G is equipped with advanced G-series hydraulics, a stable mobile undercarriage (also available with a crawler option), and an elevating cab that offers superior visibility for operators. Its modular design allows for flexible configurations with different attachments, making it ideal for a wide range of recycling tasks. The machine also features easy-to-access service points, which help reduce downtime. Additionally, its smart energy management system ensures minimal fuel consumption and lower operating costs.

Key Features of the Sennebogen 826G Waste Material Handler

Low Operating Machine Costs

Low Operating Machine Costs

The new Sennebogen 826G is engineered to deliver maximum performance while keeping operating costs low, making it an ideal choice for recycling and waste handling applications. Its fuel-efficient, Stage V-compliant engine reduces both fuel consumption and emissions while providing the necessary power for heavy-duty material handling tasks. Built with a rugged, high-quality structure and durable components, the Sennebogen 826G ensures extended service life and minimised downtime, offering long-term value and lower maintenance costs. For businesses focused on maximising ROI, the Sennebogen 826G stands out as a reliable and cost-effective solution for demanding, continuous operations in waste management.

Available with both wheeled and crawler undercarriage options, the Sennebogen 826G can be tailored to meet the specific needs of your site. The wheeled undercarriage provides high mobility and manoeuvrability for quick transitions between work areas, while the crawler undercarriage offers superior stability and control, especially on uneven surfaces. The metal tracks on the crawler version also provide a more durable and long-lasting option compared to rubber tires, making the 826G a versatile choice for recycling plant operations.

The latest addition to the Sennebogen material handlers, the G-series features in the Sennebogen 826G include a spacious and comfortable cab, designed to enhance operator efficiency and comfort. The new 826G is equipped with advanced hydraulic systems, including hydraulic valves and lines, that enable precise, overlapping movements during material loading and sorting tasks. With a wide range of attachments available, including the versatile orange peel grab, the Sennebogen 826G is fully equipped to handle a variety of waste recycling challenges, solidifying its position as a powerful material handler for recycling applications.

REQUEST A QUOTE

Advanced Hydraulic System for Maximum Efficiency and Reliability

Advanced Hydraulic System for Maximum Efficiency and Reliability

With SENNEBOGEN’s G-series hydraulic technology, the new 826G achieves maximum efficiency and precision. The load-sensing hydraulic system delivers power on demand, reducing fuel consumption without compromising performance. With an operating weight of up to 31.7 tonnes, this powerful material handler is ideal for waste recycling. The impressive 13-meter reach allows for effective sorting in waste management operations. As the latest addition to the Sennebogen recycling family, the 826G is designed to handle material efficiently, maximising throughput per work cycle. The newly designed cab enhances operator comfort, ensuring that the machine retains its value over time.

REQUEST A QUOTE

The Maxcab: Designed for Operator Comfort

The Maxcab: Designed for Operator Comfort

The Sennebogen 826G’s operator-friendly MaxCab design ensures exceptional comfort and visibility, even in demanding environments. The elevated, spacious cab provides an unobstructed view of the work area, enabling operators to manage material handling tasks with precision and ease. Featuring ergonomic joystick controls for intuitive operation, the cab offers optimal control with minimal effort. Equipped with a heated, air-suspension seat, the 826G ensures a comfortable workspace for extended shifts, enhancing both operator productivity and well-being.

REQUEST A QUOTEStay Updated with the Latest on the Sennebogen 826G

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the 826G.

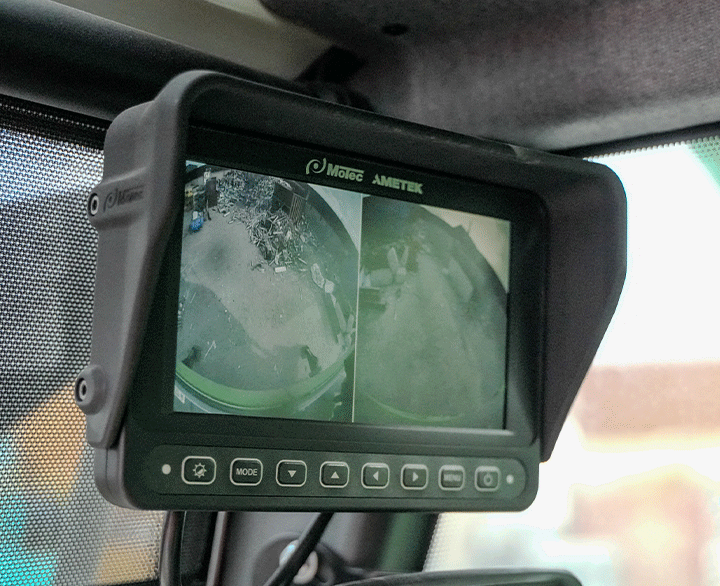

Safety first with the 826G

Safety is at the core of the 826G waste handler’s design. From its elevated cab, offering enhanced visibility, to robust safety features like pipe fracture protection and optimal camera monitoring, it provides peace of mind in busy recycling environments. The powerful 826G machine, with an operating weight of up to 31.7 tonnes and an impressive reach of 13 meters, is designed to handle waste efficiently while prioritising safety.

Scrap Handling Solutions Built for Your Industry

Discover how the SENNEBOGEN 826G Scrap Handler, a powerful material handler for recycling, can enhance your scrap processing operation. With its impressive reach of 13 meters and optimised hydraulics, it’s designed for maximum safety and efficiency in demanding continuous operation. This latest addition to the SENNEBOGEN recycling family sets new standards in material handling, making it the ideal solution for scrap and recycling yards. Visit the Molson site for machine specs, latest news, and real customer stories.

January 16, 2026

January 16, 2026