875G Port Handler

Port Handlers

Specifications

Sennebogen 875G Hybrid Port Handler for Bulk & Cargo Handling

High-capacity 32m reach electric or diesel hybrid port handler built for efficiency

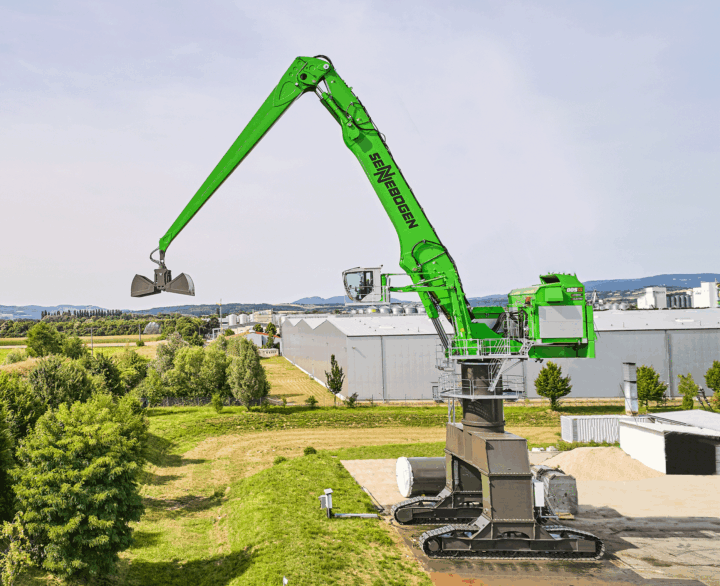

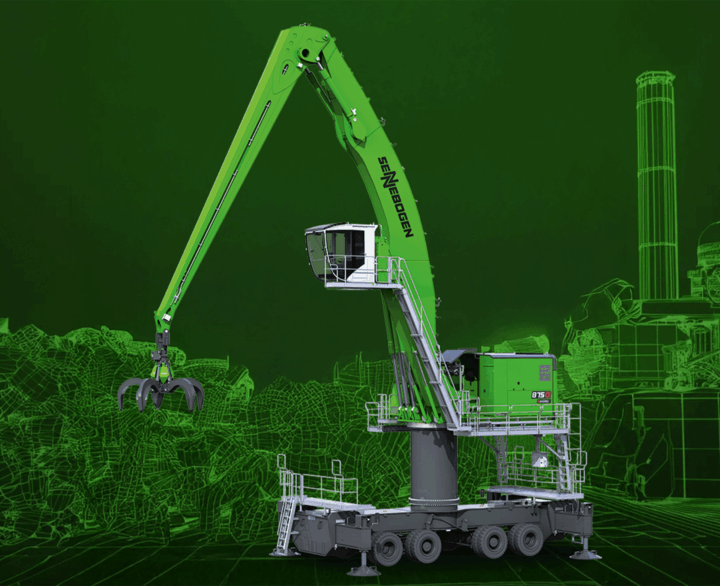

The Sennebogen 875 G-Series Port Handler is engineered for large-scale port operations, delivering exceptional efficiency, reach, and lifting capacity for bulk, breakbulk, scrap, and cargo handling. Designed with Sennebogen’s proven Green Efficiency drive systems, the 875G offers operators the choice of diesel, electric, or hybrid power solutions, helping to reduce fuel consumption, emissions, and operating costs significantly. The innovative green hybrid energy recovery system enhances performance with minimal energy consumption.

With an operating weight of up to 165 tons and a maximum reach of up to 32 metres, the 875G combines strength with stability, ensuring safe and productive cargo handling. Whether unloading ships, stockpiling bulk materials, or transferring scrap, the 875 G is built for continuous duty cycles and long service life in demanding port handling environments. Its configuration options and customer-specific undercarriage allow for optimal adaptation to various material handling tasks.

Key Features of the Sennebogen 875G Port Handler

Outstanding Reach & Lifting Capacity and Fast Cycle Times

The 875 G features a maximum reach of up to 32m, making it ideal for unloading Panamax-class ships and handling bulk cargo directly from vessel to stockpile or conveyor. Its robust boom and stick design ensures safe, stable lifting of heavy loads while maintaining smooth, precise handling performance. This port material handler is part of the modern G-series, designed for demanding port handling applications with a focus on operator comfort and energy savings for efficient handling. With its innovative green hybrid energy recovery system, the Sennebogen 875 G hybrid maximises performance while minimising operating costs.

Efficient Drive Technology with Big Fuel Savings

Efficient Drive Technology with Big Fuel Savings

Available in diesel, electric, or hybrid drive, the 875 G enables operators to choose the most efficient power solution for their operation. Sennebogen’s Green Efficiency system delivers significant fuel savings, and reduced emissions, making the machine both eco-friendly and cost-effective. With a mobile material handler configuration and a reach of up to 32 metres, it excels in general cargo handling while providing operator comfort and performance with minimal energy consumption.

REQUEST A QUOTE

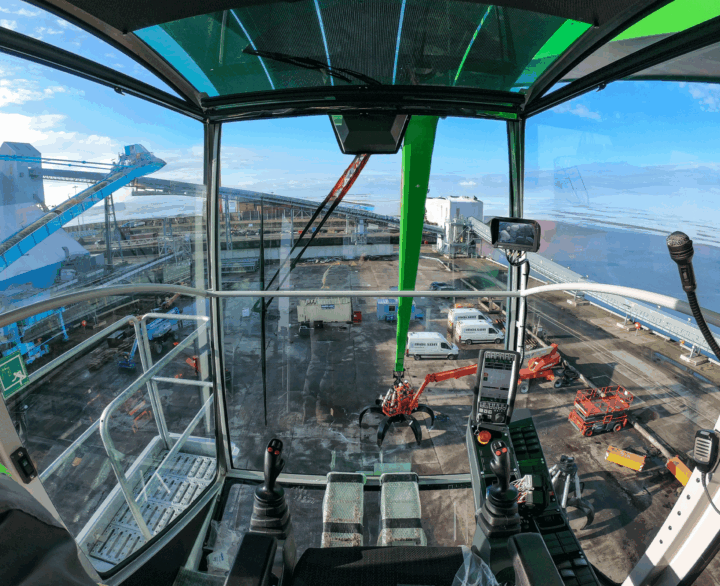

Operator Comfort & Visibility

Operator Comfort & Visibility

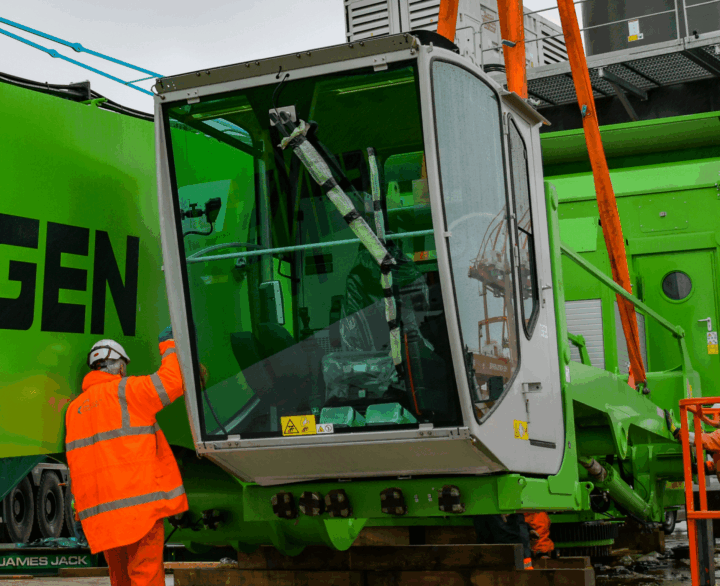

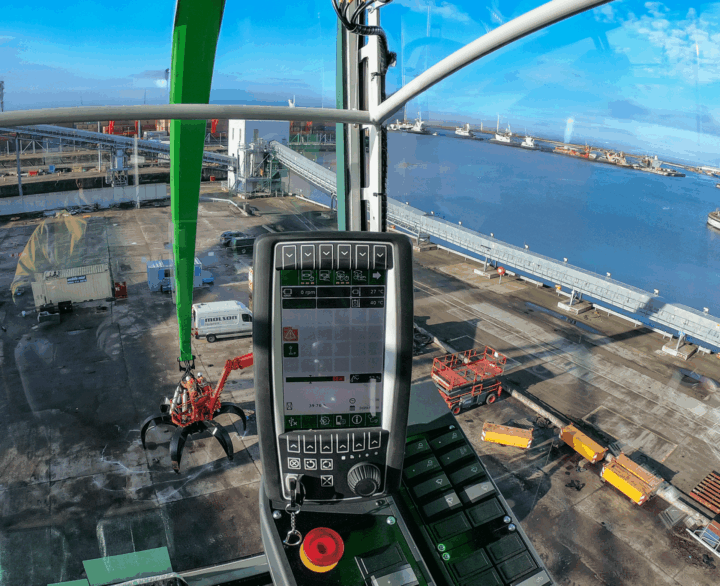

The Sennebogen 875 G is equipped with a 10-inch touch display and a Portcab comfort cab, which can be hydraulically elevated to provide operators with a commanding view over ship holds and cargo areas. Ergonomic controls, panoramic visibility, climate control, and low-noise operation ensure maximum operator comfort during long shifts. With an operating weight that supports general cargo handling, this largest material handler is equipped with a mobile undercarriage and configuration options that cater to customer-specific needs, ensuring optimal handling performance.

REQUEST A QUOTE

Designed for Continuous Duty and Efficient Cycle Times

Designed for Continuous Duty and Efficient Cycle Times

Built for heavy-duty, round-the-clock operations, the modular 875 G port handler features reinforced undercarriages, high-capacity hydraulic systems, and robust components designed for demanding port handling. Easy-access service points and intelligent diagnostics simplify maintenance, reduce operating costs, and extend machine life. The 875 G hybrid design incorporates a green hybrid energy recovery system that enhances performance with minimal energy consumption.

REQUEST A QUOTEPrioritising Safety in Busy Work Zones

The new Sennebogen 875G material handler isn’t just about delivering exceptional lifting power; it’s engineered with operator safety at its core. Featuring outstanding all-around visibility and advanced integrated safety systems—such as pipe burst protection and optional camera configurations—the 875G ensures peace of mind in demanding environments. Whether working in congested ports or managing unpredictable bulk materials, this powerhouse supports a safe, efficient, and controlled operation. As part of the innovative G-series, the 875G combines cutting-edge technology with proven material handling performance.

Stay Updated with the Latest on the Sennebogen 875G

Discover the latest news, stories, and updates from the Molson site. Whether it’s product highlights, behind-the-scenes action, or industry insights, this is where you’ll find everything connected to the 875G.

Ready for the Demands of Port Terminals and Harbours

Built for precision handling, fast cycles, and continuous throughput, the Sennebogen 835G Hybrid excels in busy port terminals. Its energy-saving hybrid system, flexible undercarriage options, and operator-first design make it the go-to solution for those seeking to increase capacity while reducing costs and emissions.

November 24, 2025

November 24, 2025